MATERIALS.IE

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites • Coatings

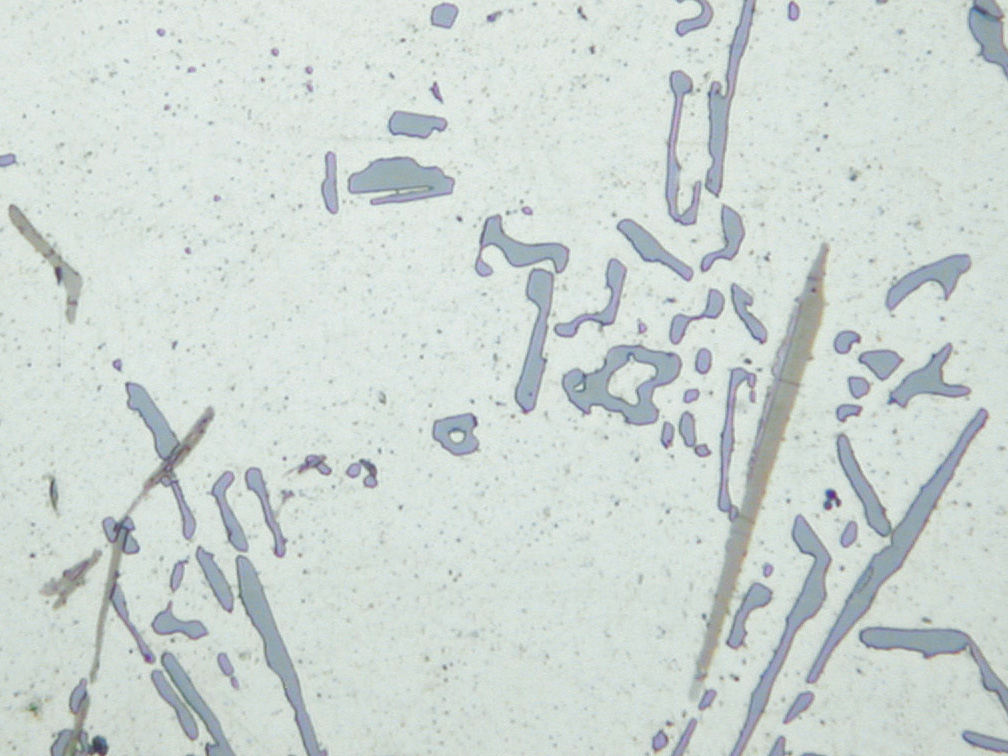

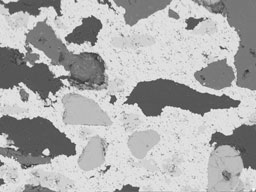

METALS

Materials

Extensive materials experience includes:- Irons

- grey cast iron

- white cast iron

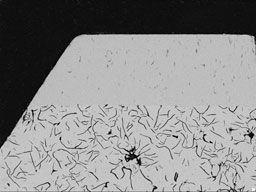

- Steels

- plain carbon

- alloy

- microalloy steels

- stainless

- powder metal

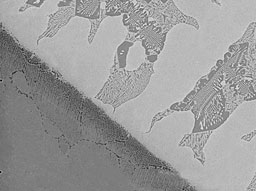

- Aluminium alloys

- Magnesium alloys

- Titanium alloys

- Copper alloys

- brasses

- bronzes

- Refractory metals

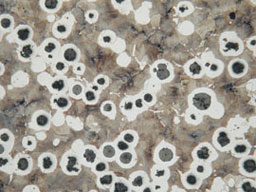

- Metal matrix composites

- particulate reinforced

- short fibre reinforced

- continuous fibre reinforced

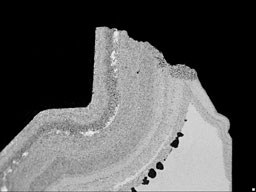

- Surface treatments

- case hardening

- plating

- thermal spraying

- PVD

- CVD

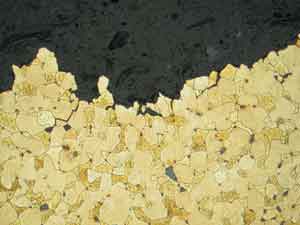

- Tribological materials

- plain bearings

- aluminium alloy

- copper alloy

- white metal

- friction materials

- sintered

- Sealing materials

- gaskets

Processes

Comprehensive process knowledge includes:- Casting

- sand

- gravity die

- pressure die

- lost wax

- continuous

- squeeze

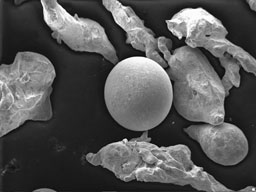

- Powder metallurgy

- cold compaction

- steel

- aluminium

- copper

- warm compaction

- hot compaction

- isostatic pressing

- powder rolling

- injection moulding

- 3D-printing - laser sintering

- porous materials

- Rolling

- Forging

- Extrusion

- continuous

- Heat treatment

- Welding

- Brazing

- Soldering

Applications

Application experience includes:- Automotive

- powertrain

- valvetrain

- brakes

- suspension

- body panels

- Industrial

- lifting equipment

- hydraulics

- valves

- heat exchangers

- boilers

- press tooling

- cutting tools

- catering equipment

- Aerospace

- Railway

- locomotive

- Marine

- valves

- deck fittings

- Domestic products

- electrical contacts

- pipes and plumbing fittings

- Medical devices

- Electronic devices

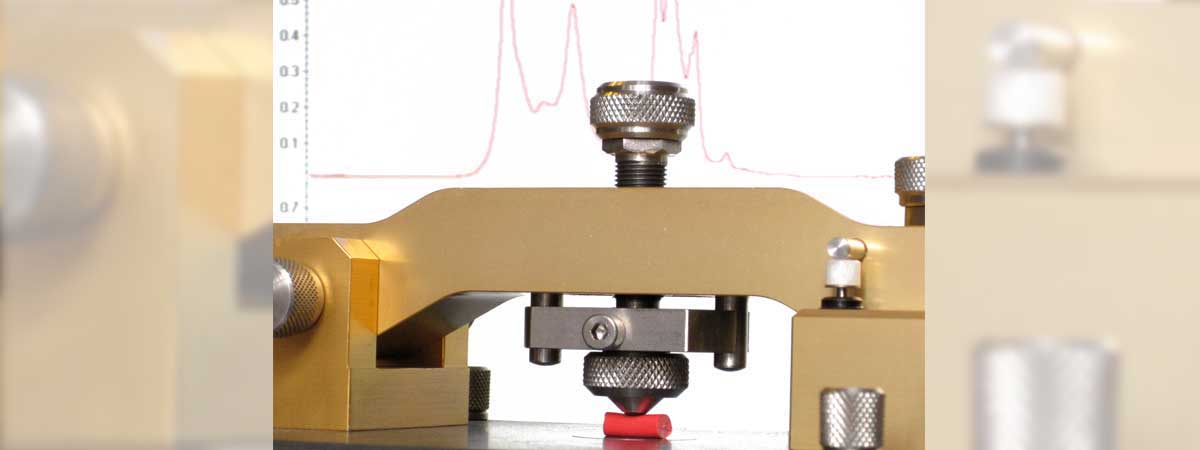

Failure Mechanisms

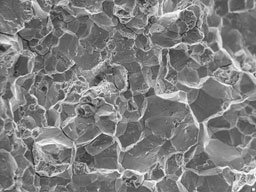

Failure experience includes:- Fracture

- fatigue

- corrosion

- rolling contact

- fretting

- brittle

- intergranular

- cleavage

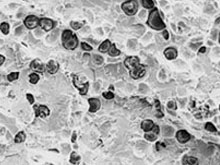

- ductile

- microvoid coalescence

- Corrosion

- pitting

- galvanic

- intergranular

- stress-corrosion

- hydrogen embrittlement

- erosion & cavitation

- dezincification

- oxidation

- Wear

- abrasive

- cavitation erosion

- adhesive wear

- fretting wear

- Distortion